Tailor-made precision

Bespoke components for your production processes.

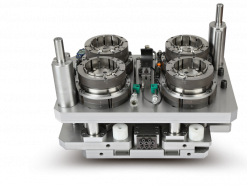

We specialize in designing and building plastic injection molding, die casting and foaming tools, as well as highly complex assembly equipment and other production machinery. We can help you develop individual products, or take complete responsibility for complex assembly systems. Whether you need product and process development or machine and tool maintenance, our team of experts can help.

Technology and know-how — the perfect combination.

Here's an overview of our business activities:

Product portfolio

Our portfolio: Results that

speak for themselves.

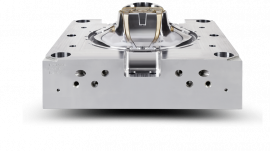

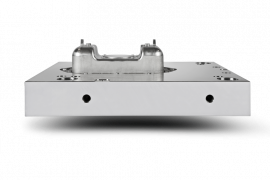

- Plastic injection molds

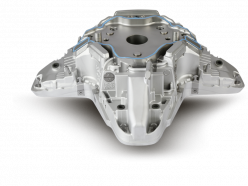

- Die casting molds

- Trimming tools

- Foaming molds

- Prototype molds

- Prototypes

- Production and

special machinery

- Our wide-ranging expertise means we can build just about any tool you care to mention. Please contact us to discuss your specific needs.

References

Project

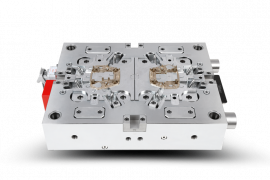

Plastic injection tools for child seats

Projectinformation

Plastic injection tools for child seats

Our teams in Aschaffenburg and Arad designed and produced nine injection molded tools for sixteen plastic parts used in series production of TAKATA MINI child seats. To produce the components as cost-efficiently as possible, several family molds were made for various groups of components.

Tool details:

- Dimensions L x W x H: 400 × 450 × 330 to 1380 × 1730 × 1380

- Tool weights: 400 to 12,500 kg

- Tool technologies: Internal gas pressure using cascade control

- First parts from the complete toolset available after 15 weeks

Joyson Tooling — a partner you can rely on.

We believe that successful collaboration is about more than project planning. We also offer full project management, giving you a clear view of the current situation at every stage. We see ourselves as a key link in the production chain — one where efficiency is paramount.

We focus on cost-efficiency at every stage of the project, and ensure that every tool and machine we make offers total reliability.